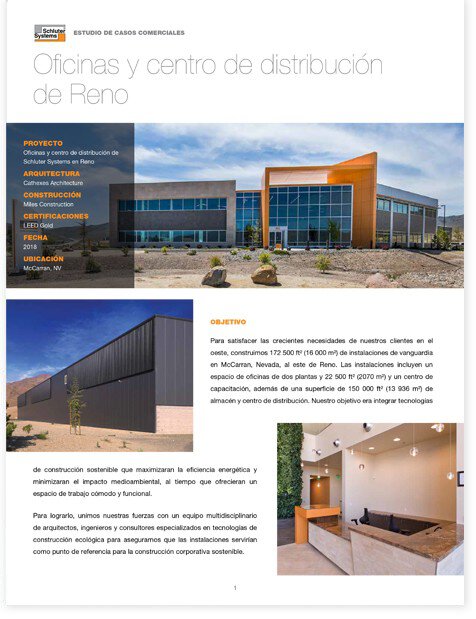

Presentando la construcción corporativa sostenible: oficina y centro de distribución de Schluter en Reno

Proyecto:

Oficinas y centro de distribución en Reno

Certifications:

LEED Gold

Arquitectura:

Cathexes

Architecture

Fecha & Ubicación:

2018 McCarran, NV

Objectivo

Para satisfacer las crecientes necesidades de nuestros clientes en el oeste, construimos 172 500 ft² (16 000 m²) de instalaciones de vanguardia en McCarran, Nevada, al este de Reno. Las instalaciones incluyen un espacio de oficinas de dos plantas y 22 500 ft² (2070 m²) y un centro de capacitación, además de una superficie de 150 000 ft² (13 936 m²) de almacén y centro de distribución. Nuestro objetivo era integrar tecnologías de construcción sostenible que maximizaran la eficiencia energética y minimizaran el impacto medioambiental, al tiempo que ofrecieran un espacio de trabajo cómodo y funcional.

Para lograrlo, unimos nuestras fuerzas con un equipo multidisciplinario de arquitectos, ingenieros y consultores especializados en tecnologías de construcción ecológica para asegurarnos que las instalaciones servirían como punto de referencia para la construcción corporativa sostenible.

Desafío

Conscientes de nuestra huella medioambiental, hemos implementado medidas para reducir significativamente el consumo de energía y agua. También priorizamos el bienestar de nuestro personal diseñando un espacio de trabajo en el que cada cubículo se beneficia de la luz natural y de la circulación de aire fresco.

Durante la construcción, empleamos prácticas de control del sitio para mantener la sostenibilidad, tales como estaciones de lavado de neumáticos para evitar la propagación de escombros, filtración y reutilización del agua utilizada en el lugar y un reciclaje exhaustivo de los materiales de construcción. Además, nos aseguramos de que todos los materiales (sellantes, baldosas y acabados) estuvieran libres de compuestos orgánicos volátiles (COV) y de que se inspeccionaran antes de ser utilizados para detectar posibles emisiones de gases.

Solución

Calefacción y refrigeración sostenibles

Sistema geotérmico: El edificio se calienta y se enfría en su totalidad mediante un sistema geotérmico que consta de 36 pozos subterráneos. Este sistema transfiere energía entre la tierra y la instalación a través de la calefacción y refrigeración hidrónicas, lo que reduce drásticamente la demanda de energía.

Intercambiador de calor de la tierra: Un «túnel canadiense» de 200 ft (60 m) de largo y 3 ft (90 cm) de diámetro acondiciona el aire fresco antes de que entre en las instalaciones, lo que reduce la carga de trabajo de los sistemas de climatización.

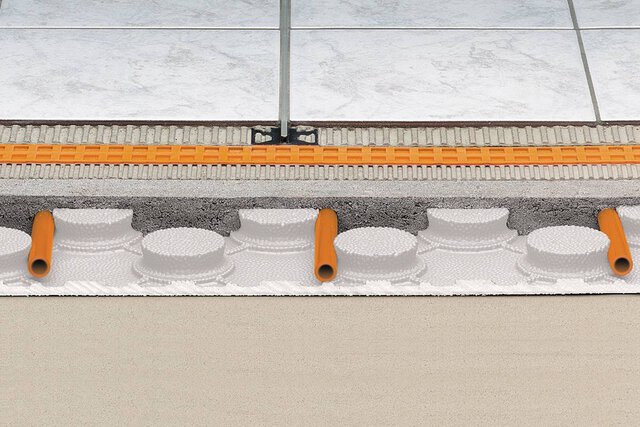

Sistema modular de recrecido Schluter®-BEKOTEC: ofrece una calefacción radiante de gran eficiencia en el piso. El sistema reacciona cuatro veces más rápido que los sistemas tradicionales y funciona a temperaturas más bajas, reduciendo así el consumo de energía.

Eficiencia energética y ahorro de costos

Los edificios de oficinas tradicionales de la región suelen incurrir en costos de energía de $1.35 a $1.55 por ft². Nuestras instalaciones operan, aproximadamente, a $ 0.44 por ft², lo que representa un ahorro del 70-75 %.

- Consumo de energía (por periodo de 6 meses):

- Electricidad: 220 048 kWh

- Gas: 201 termias

- Agua: 247 302 galones (936 000 L)

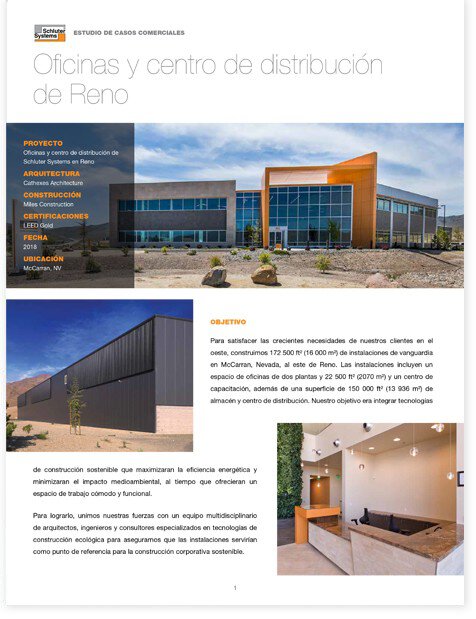

Luz natural y calidad del aire

Los tragaluces de alto rendimiento maximizan la luz natural en almacenes y áreas de trabajo.

La iluminación automatizada se activa solo cuando es necesario, lo que reduce el desperdicio de energía.

Una pared verde con más de 200 plantas mejora la calidad del aire interior al absorber CO2, añadir oxígeno y filtrar COV.

El sistema de ventilación con control de CO2 mantiene una calidad de aire interior confortable a 650 ppm (muy por debajo de los límites reglamentarios).

Gestión del agua y de los recursos

Los paneles solares para el calentamiento de agua proporcionan agua caliente a las instalaciones.

La reutilización del agua de lluvia y de la utilizada en la construcción redujo la demanda inicial de agua y el consumo a largo plazo.

El techo blanco reflectante mitiga la absorción de calor, reduciendo la demanda de refrigeración.

Resultado

La oficina y el centro de distribución de Reno ejemplifican el compromiso de Schluter con las prácticas de construcción sostenible. Mediante la integración de energía geotérmica, calefacción solar, ventilación avanzada y amplias aplicaciones de baldosas, hemos creado instalaciones extremadamente eficientes y ecológicas que benefician tanto a la empresa como a la comunidad.

Productos utilizados

DITRA-XL MEMBRANA DE DESACOPLAMIENTO 3'3" X 53'3" = 175 FT2

Membrana de desacoplamiento e impermeabilizante

RONDEC/QUADEC CONECTOR 3/8" PARA PERFILES DE ALUM

Perfil de protección de canto con superficie de reborde redondeada

Schluter®-

DILEX-AHK

Perfil de media caña para esquinas interiores de pared y transiciones piso/pared